Discover the Versatile Utilizes of Membrane Switch Over in Modern Electronic Devices

In the realm of modern electronics, the application of membrane switches is remarkably comprehensive, extending from smooth consumer gizmos to crucial clinical gadgets. These thin, flexible user interfaces not just enhance gadget procedure with their responsive responsiveness however likewise substantially boost toughness by standing up to ecological threats like moisture and dirt. As sectors proceed to develop, the combination of membrane layer switches in tools style is pivotal, promising not just to satisfy however go beyond the rigorous needs of both capability and visual appeal. Discover extra regarding exactly how these components are forming the future of technology.

Checking Out the Role of Membrane Switches in Customer Electronics

Why are membrane switches over so common in customer electronics? Membrane switches are cost-effective to make, making them an attractive choice for high-volume manufacturing regular in consumer electronics.

Moreover, these switches are known for their durability and low maintenance. From microwave stoves to remote controls, membrane layer buttons provide a useful, user-friendly user interface that supports the dynamic nature of consumer electronics.

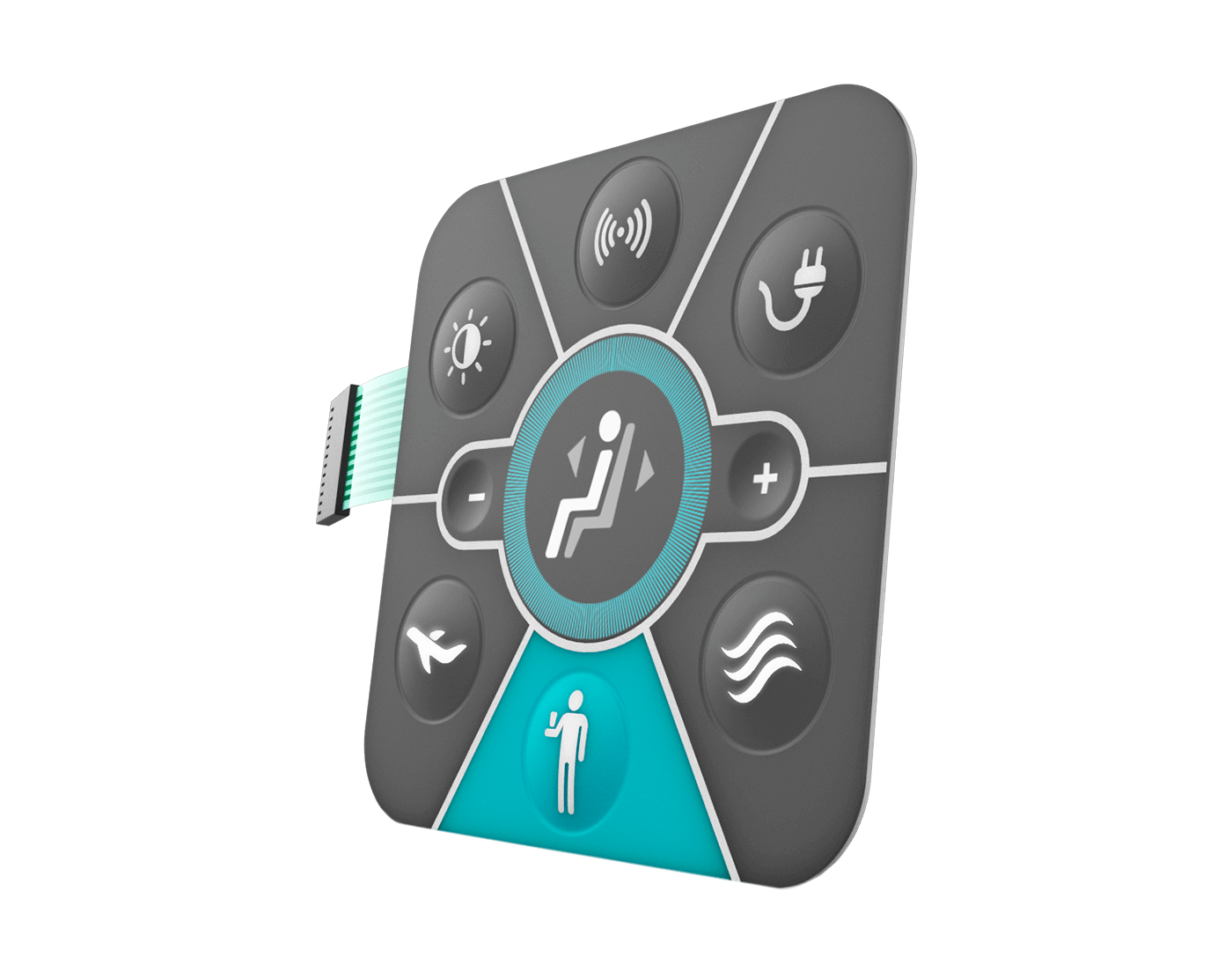

Membrane Changes in Medical Instruments: Enhancing Interface

Membrane layer buttons also play a significant duty in the realm of medical gadgets, where they boost interface with their distinct advantages. These buttons are especially valued for their reliability and ease of cleanliness, vital in healthcare settings where cleanliness is paramount. The smooth, closed surface area of membrane switches over allows for easy disinfection, minimizing the threat of contamination and spread of virus. Additionally, their layout flexibility accommodates the ergonomic and aesthetic needs of clinical equipment, making gadgets more instinctive and available for health care specialists.

Membrane buttons likewise contribute to the longevity of clinical devices. Their resistance to contaminants and fluids guarantees that critical equipment stays functional in different clinical setups, including surgical treatments where exposure to fluids is common. This durability, combined with tactile feedback and inconspicuous design, makes membrane layer switches an integral element in enhancing the performance and safety and security of medical tool user interfaces.

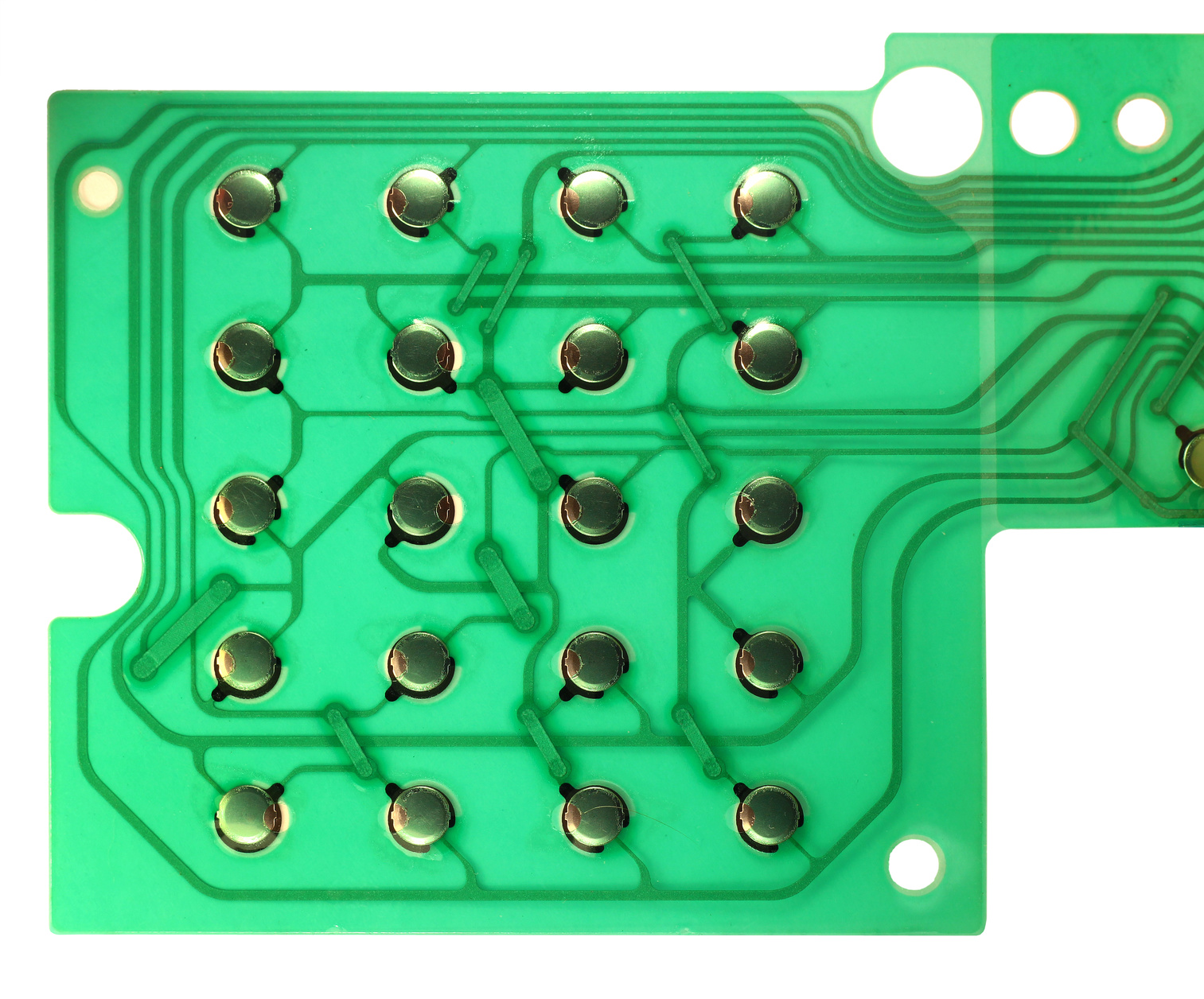

The Impact of Membrane Activates Industrial Tools Style

In the world of industrial equipment layout, the consolidation of membrane layer buttons has actually noted a considerable advancement. These switches have changed exactly how makers come close to interface capabilities, offering a mix of sturdiness and versatility that is necessary in harsh environments. The slim profile of membrane layer switches permits even more small maker styles, while their resistance to water, chemical, and dirt pollutants makes them optimal for industrial settings. This versatility has actually promoted the development of equipment that is not just more durable yet also much easier to keep and tidy, click this link thus lowering downtime and functional expenses.

Moreover, the customizability of membrane layer changes makes it possible for designers to integrate details tactile responses and visual overlays that enhance the user experience and boost performance. This assimilation sustains operators in achieving accuracy control over complex equipment. The overall impact is a considerable improvement in the performance, reliability, and user-friendliness of industrial devices, straightening with the increasing needs for my site technical innovation and operational efficiency in modern-day sectors.

Conclusion

Membrane buttons have transformed modern electronics, supplying streamlined, durable, and personalized interfaces throughout different fields. This modern technology not only meets the demanding conditions of various fields however also considerably enhances individual experience, making membrane layer changes a keystone of contemporary digital style.

In the world of modern electronic devices, the application of membrane layer buttons is incredibly considerable, extending from sleek consumer gizmos to essential clinical tools.Why are membrane switches over so prevalent in customer electronic devices? Membrane buttons are cost-efficient to produce, making them an attractive choice for high-volume manufacturing regular in consumer electronic devices. From microwave stoves to remote controls, membrane switches offer a sensible, user-friendly interface that sustains the dynamic nature of consumer electronic devices.